Manny Salazar, the Manager at Automated Integration LLC, wrote an article titled Roller Coaster Overhaul for the April 2018 issue of Automation World. The article told the story on how Automated Integration replaced an old PLC, a bunch of relays and what seemed like miles of wire when upgrading the control and safety system on the Hurricane roller coaster in a New Mexico amusement park.

An AutomationDirect Case Study

The Hurricane roller coaster had been around for years. Installed in 1992 on the Santa Cruz Boardwalk in California, it was disassembled and moved, using 12 semi-trucks, to Western Playland Amusement Park in Sunland Park, New Mexico. After a month of sanding, painting and reassembly; the amusement park had a shiny, re-commissioned roller coaster ready to roll in the spring of 2015.

But after recommissioning at its new location, the ride was unreliable, had intermittent problems, and was difficult to maintain. The control system was the problem, it was constantly breaking down. Much of the control system was relay-based, with lots of interconnecting wires, supplement by an old Siemens PLC. Many parts were obsolete, and the design made troubleshooting difficult.

Fortunately, Automated Integration was able to upgrade the coaster by adding a new AutomationDirect Click PLC and other control hardware. Automation design, maintenance, repair, and programming services were also needed for the upgrade, and all went well. The fun started during extensive live testing.

The Clitter-Clatter of Failing Relays

When Salazar arrived, he noted the entire control system was failing. It was a mess and the ride would not run reliably. Sometimes the chain drive used to pull the coaster to the top of the first hill would shut down. Sometimes the safety interlocks for the cars would fail, stopping car movement. The sensors used to determine speed and car position around the track were failing as well. For example, the sensors would fail to indicate a car was in the correct position to begin the ride, inhibiting the control system from starting the ride. The failures were numerous and were occurring more frequently.

The original control system was primarily relay-based, with a small Siemens S5-100U PLC used for braking purposes.

A big problem was the complexity of the hardwired relay control circuits. Intermittent faults and random failures happened often, and were difficult to fix.

A Little Brakes Please

Like any roller coaster, the Hurricane is a fun ride. It’s about 55 feet tall, can reach speeds near 60 mph, and exceeds 4 G around turns with its screaming passengers onboard. The ride lasts about 50 seconds with almost 1500 feet of steel track. Throughout the ride, the two 12-passenger trains, with three 4-person cars each, needs to slow down or stop, depending on the zone.

Two sets of cars alternate. The press of a start button releases a full train up the hill if an empty one is present just upstream of the start. The full train is dragged up the hill, where it then runs free and coasts until the last zone is reached, the unload area, unless it is blocked (stopped) for some safety reason monitored by the control system.

The breaking system consists of pneumatic brakes and electromagnetic braking in the motors, both controlled by the PLC. Magnetic brakes are used to slow the train at key points of the ride, and require no control other than brake force adjustment.

Modernizing Control

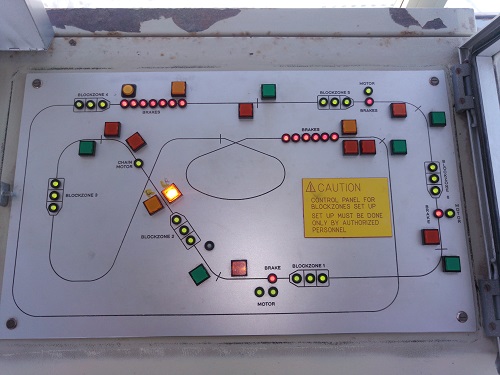

An AutomationDirect Click PLC was chosen to replace the old PLC and many of the relays. The PLC is used in a “dual-rack” configuration and controls all ride operations. It also controls the air compressor system and braking systems and monitors the position of the trains in the ride. The PLC monitors positions of the train cars and determines whether to allow them to proceed to the next station (blockzone) in the ride.

New pressure switches were added, and the PLC monitors their status to verify pneumatic and electromagnetic brake operation. Failures, such as air pressure problems, create alarms to shut down the ride. E-stops are also monitored by the PLC.

Safety relays and contactors are used to control the five motors used throughout the ride. They are also used to control the variable frequency drives, and to monitor the lap bar release system.

The new Click PLC provided the logic for speed control. One of the main control requirements was to limit the speed the cars could travel during the ride. The original ride specifications specified the cars could reach 60 mph. There was concern that the existing proximity sensors would be able to detect the car traveling at that speed, register it in the PLC and calculate train speed—all within a very short window of time.

With a new Click PLC and new inductive proximity sensors at the entrance and exit of each zone (station), the control system was fast enough to detect and monitor the cars in six different zones reliably and repeatably.

AutomationDirect Roller Coaster Control

The design uses two full racks of PLC components. Each rack has a controller and a power supply. The main rack has eight 16-point, 24 VAC/VDC discrete input modules. The second rack has eight 6-point, 5-27 VDC, discrete output modules. AutomationDirect ZIPLink pre-wired connection cables and modules were used to simplify wiring of the many I/O points. The Click PLC was selected due to the low cost of the controller and related hardware, and for its ability to handle all control functions reliably.

The new control system took a lot of work, especially removing the original relays and control panels, and there was significant PLC-controlled I/O to terminate. It was also necessary to work closely with the operators and owner during development of the new control system’s functionality, and to detail operating procedures.

How was it tested? To start, many basic tests were performed without riders, just sand bags in the train cars. After initial testing, willing volunteers were used. We did a lot of testing, but this automation project startup was much more fun than many others because we got to ride a roller coaster!

The result is a safe, reliable and simple to operate roller coaster that is easier to maintain.

To read more articles about AutomationDirect, click here.